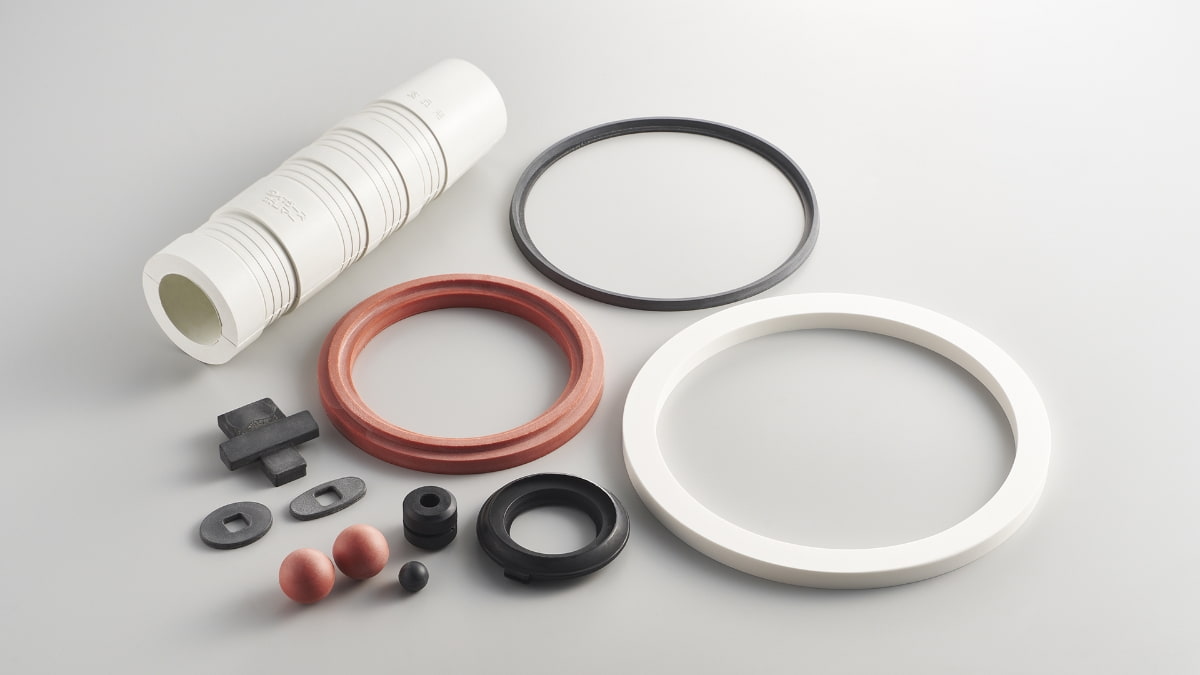

Rubber Molded Products Rubber Molded Products

| Rubber Injection Molding |

With a mechanism similar to an extruder, plasticized and preheated material is quickly filled into a mold set at the vulcanization temperature, and rubber products are formed and vulcanized in a short time. |

|---|---|

| Compression Molding |

After putting the rubber compound (material) into the mold cavity and assembling the mold, it is placed between the hot plates of a heated vulcanization press, and the hot plates are pressurized to form and vulcanize the rubber product. |

| Transfer Molding |

This is a molding method that uses a mold with an injection chamber (concave pot) and a piston (convex) on it. By placing a nearly constant amount of unvulcanized rubber (material) into the concave pot and pushing the piston (convex) with a press, the material is filled into the cavity through the spool. |

| Rubber: Mandrel Molding |

This method is mainly used to manufacture rubber hoses. |

| Liquid Injection Molding |

This is mainly an injection molding method for thermosetting materials that are liquid at room temperature, such as silicone. A product is made by filling a mold with liquid material and then solidified using a chemical reaction. |

Inquiry for Details of Our Products

Product specifications, dimensions, and designs are subject to change without notice due to improvements, etc.